XRay Inspection System

Price 8000 USD ($)/ Piece

XRay Inspection System Specification

- Language Support

- Multi-language including English, Chinese

- Usage

- Industrial product inspection, security checkpoint, laboratory analysis

- Compatible System

- Windows, Linux

- Support System

- Real-time monitoring, remote update capability

- Security Features

- Automatic alarm for irregular objects, high precision imaging, multiple-level access control

- Interface Type

- Touch screen interface, USB and Ethernet connectivity

- Capacity (Person)

- Single operator per unit

- Type

- Digital X-Ray Inspection System

- Application

- Automated detection of internal defects in products, quality control in manufacturing, and security screening

XRay Inspection System Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1-7 Days

About XRay Inspection System

Superior Imaging and Detection

This X-Ray Inspection System provides high-precision imaging with automatic defect marking and real-time analysis. Its minimum detectable size of 1.5 mm and image enhancement software ensure no irregularity goes unnoticed, supporting accurate quality control and security applications.

Efficient and Safe Operation

Complying with international X-ray safety regulations, the system incorporates a comprehensive alarm system and multi-level access controls. Its visual and audible alerts guarantee quick response when suspicious objects are detected, ensuring operator safety is never compromised.

Versatile Connectivity and Export Options

With USB and Ethernet interfaces, data can be exported in JPG, PNG, and PDF formats for easy documentation and sharing. This flexibility supports seamless integration into different operational setups and maximizes compatibility across Windows and Linux systems.

FAQ's of XRay Inspection System:

Q: How does the X-Ray Inspection System enhance quality control in manufacturing?

A: The system utilizes high-resolution imaging and automatic defect marking to detect internal faults as small as 1.5 mm, allowing operators to efficiently identify and address issues during the production process. Real-time analysis further streamlines decision-making, ensuring consistently high product standards.Q: What types of products and environments can this inspection system be used for?

A: It is designed for industrial product inspection, laboratory analysis, and security checkpoint applications. The unit's robust construction and precision detection capability make it suitable for inspecting various materials and products, especially in manufacturing lines and airports.Q: When should X-ray inspection be implemented during the production process?

A: X-ray inspection is recommended at critical quality checkpoints, either during intermediate product stages or as a final inspection before packaging and shipping. Early detection of defects helps prevent larger issues and reduces the risk of defective products reaching the market.Q: Where should the X-Ray Inspection System be installed for optimal performance?

A: Install the system in secure, controlled environments such as dedicated inspection areas in factories, laboratory settings, or security checkpoints. Ensure adequate space for operation, ventilation, and safety in alignment with its product dimensions and operating temperature range.Q: What is the process for operating the inspection system and exporting data?

A: Operators use the intuitive touch screen interface to start inspections. The software automatically enhances images, marks defects, and enables real-time analysis. Data can be exported in JPG, PNG, or PDF formats through USB or Ethernet for reporting or record-keeping.Q: How does the alarm system benefit security screening applications?

A: The integrated visual and audible alarm quickly notifies operators of suspicious objects or irregularities detected during the inspection. This prompt alert system, coupled with high precision imaging, heightens security and reduces response time to potential threats.Q: What support and security features are included with the system?

A: The system supports real-time monitoring, remote update capability, and multi-level access control, ensuring continual effectiveness and protection against unauthorized use. Its software features and alarms contribute to safe, reliable, and efficient inspection operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industry Inspection Equipment And Crypto Currency Category

ETH Mining Rig Ethereum Miner

Price 1500 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Support System : Windows/Linux

Language Support : English

Usage : Professional Crypto Mining

Compatible System : Windows, Linux, HiveOS

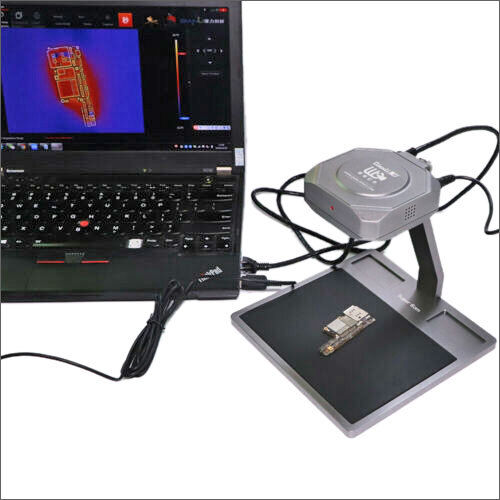

thermal Dual Camera

Price 500 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Support System : Windows, Linux

Language Support : English, Chinese, multilingual

Usage : Human body temperature detection, security monitoring

Compatible System : Windows, Linux, embedded systems

Antminer Scrypt Algorithm Miner

Price 1000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Support System : Windows/Linux compatible

Language Support : English

Usage : Professional ASIC miner for Scrypt algorithm coins like Litecoin

Compatible System : Desktop PC/server

Mining Rig Ethereum Miner

Price 2000.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Support System : Windows, Linux

Language Support : English

Usage : Industrial, Commercial

Compatible System : Ethereum, GPU Based Coins

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry